Facilities

GSP has in-house facility to carry out operations such as:

Compacting presses available from 5 to 200 Tons

State of the art sintering furnace

press available from 20 to 65 Tons

Vacuum oil Impregnation plant

State of the art sintering furnace

press available from 20 to 65 Tons

Vacuum oil Impregnation plant

Why Us?

Short Development time

Expert team of Engineers and other supporting staff

More than 3 decade of experience

Competitive prices

Small as well as big batch size welcomed

Expert team of Engineers and other supporting staff

More than 3 decade of experience

Competitive prices

Small as well as big batch size welcomed

Great quality

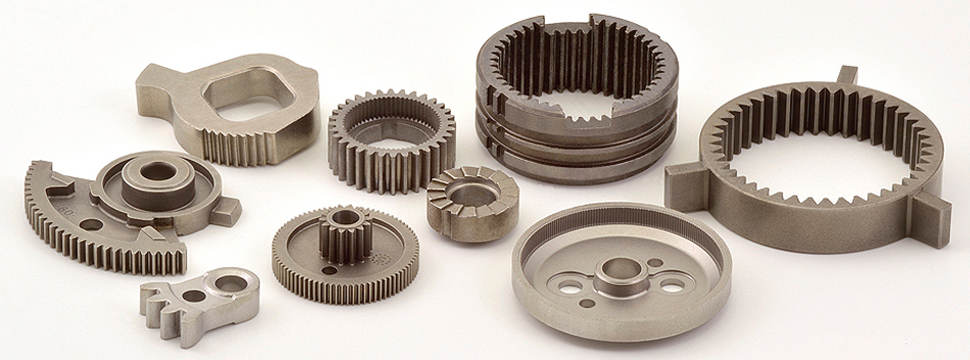

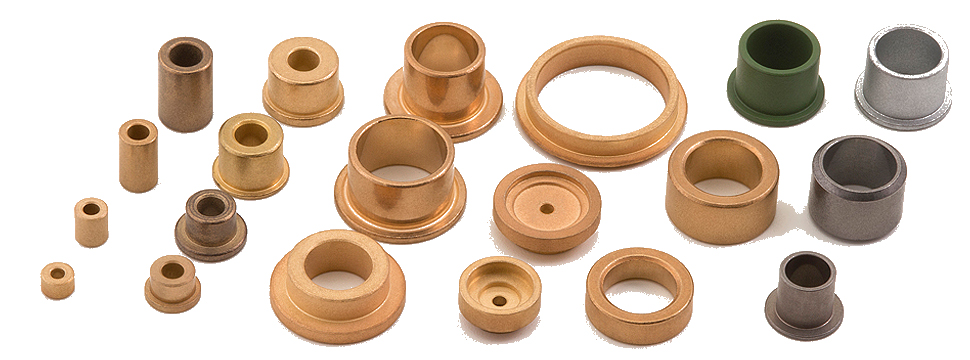

We offer products in material composition Sintered Bronze, Sintered iron, Iron Alloym Sintered Steel, that is as per IS/MPIF/ISO/DIN/JIS specification

PROCESS AND QUALITY

1

1Basic Manufacturing Process

The two basic elements for manufacturing a sintered component are:metallic powder, and tooling.

2

2Secondary Manufacturing Process

Applications of complementary operations on a sintered component allow to improve one or more characteristics not directly achievable from the basic process.

3

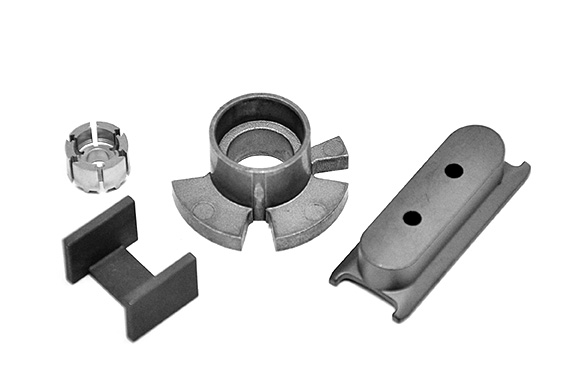

3Recommended Shapes

Sintered components should be designed based on several shape recommendations, aimed at making compacting feasible, as well as to minimize manufacturing costs